BZW-3.0+C

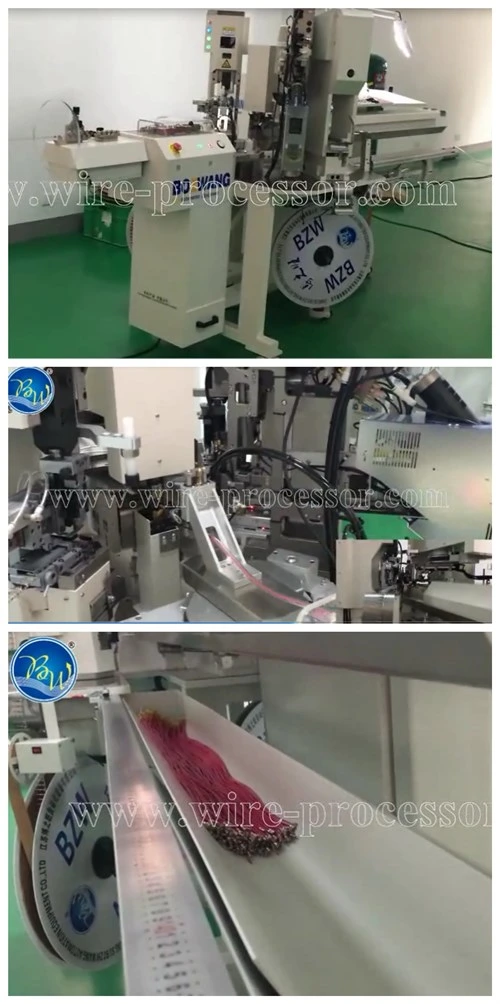

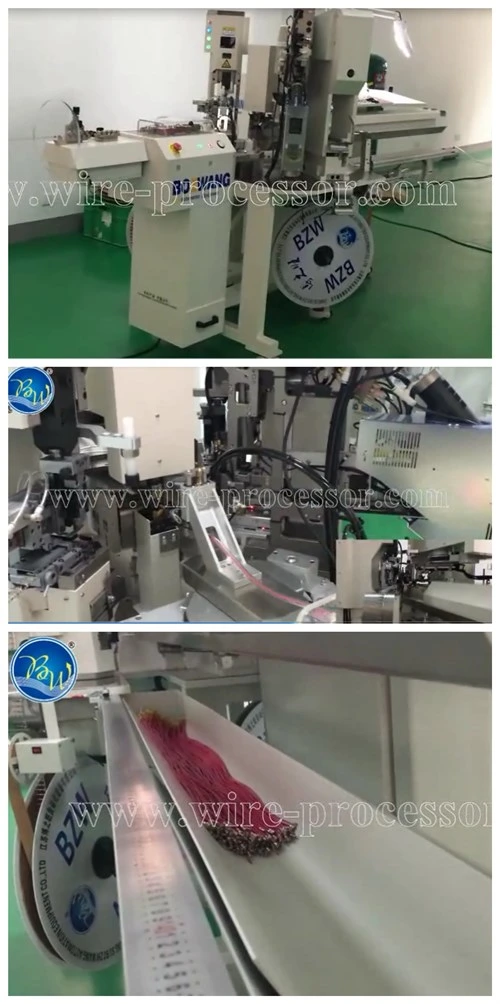

BW-3.0+C Full automatic high precise double ends crimping machine with seal threading

This advanced equipment has the higher level of processing ability and precision, with unique driving system, high speed controlling technology and rigid driving structure, to satisfy all kinds of the processing requirements of the vehicle and other wire harness industries. As a kind of national high holding machine, the advantage of its cost performance is obvious, which is widely accepted by the customers and also give them more economization and high efficiency to compete in the wire harness industry.

Product features

International appearance design, and tight and concise whole structure;

IPC controlling system, operating interface is simple and rational. The operation of the machine is easy to learn. All the parameters are easily set and stored. The images of operating indications are simple and direct;

Panasonic FP2 RTX network bus system, high precision, fast response, real time monitoring;

The crimping station is installed with imported servo motor, high crimping precision and stable performance;

The pneumatic parts are all imported SMC, high efficiency and stability with long life service;

The crimping height is automatically adjusted to realize the automation;

Full closed loop wire feeding system, rubber belt feeding device protect the surface of the wire from the damaging, increasing the feeding efficiency;

The optional two dimension coding gun and printer can manage and store the data.;

The unqualified product can be eliminated and reclaimed to reach 100% qualified rate.

Technical parameters:

Optional unit:

Advanced seal threading station.

BW-3.0+C Full automatic high precise double ends crimping machine with seal threading

This advanced equipment has the higher level of processing ability and precision, with unique driving system, high speed controlling technology and rigid driving structure, to satisfy all kinds of the processing requirements of the vehicle and other wire harness industries. As a kind of national high holding machine, the advantage of its cost performance is obvious, which is widely accepted by the customers and also give them more economization and high efficiency to compete in the wire harness industry.

Product features

International appearance design, and tight and concise whole structure;

IPC controlling system, operating interface is simple and rational. The operation of the machine is easy to learn. All the parameters are easily set and stored. The images of operating indications are simple and direct;

Panasonic FP2 RTX network bus system, high precision, fast response, real time monitoring;

The crimping station is installed with imported servo motor, high crimping precision and stable performance;

The pneumatic parts are all imported SMC, high efficiency and stability with long life service;

The crimping height is automatically adjusted to realize the automation;

Full closed loop wire feeding system, rubber belt feeding device protect the surface of the wire from the damaging, increasing the feeding efficiency;

The optional two dimension coding gun and printer can manage and store the data.;

The unqualified product can be eliminated and reclaimed to reach 100% qualified rate.

Technical parameters:

| Cross section: 0.3-5mm2 (Other size can be special ordered) Cutting length: 60-10000mm (Other size can be special ordered) Cutting precision: ±(0.2%*L+1)mm Stripping length: 0.1-18mm Feeding speed: Max. 8.0 m/s Wire collecting conveyor: 2m,4m (Other size can be special ordered) Crimping force: 30KN Power: 220V 50HZ Air supply: 0.5 Mpa-0.7 Mpa,8m3/h Weight: 1100k Dimension: 3500 x 1200 x 1700m Detecting ability: wire knotting, wire lacking, terminal lacking, crimping pressure, air pressure, bare wire and seal detecting. Applicator range: stroke is 30 and 40mm . |

Advanced seal threading station.

Pre-feeding unit: wire storage length 6m

inkjet marking system:the inkyet device can be installed

the protecting cover can be installed

the high precise measuring unit can be installed:High precise digtial micro mrter and magnifier.

imported crimping force monitoring unit:100% precion and reliable detecting

two demension code gun and printer:store all the crimping data of different applicators and wires and all the data is automatically inputted.

Company and working shop

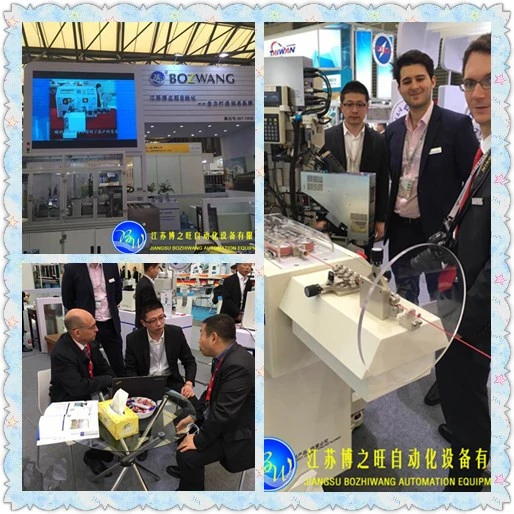

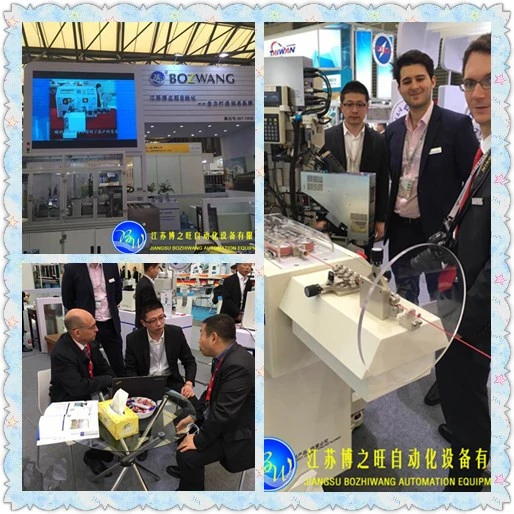

Exhibition

Certification

Contact us

inkjet marking system:the inkyet device can be installed

the protecting cover can be installed

the high precise measuring unit can be installed:High precise digtial micro mrter and magnifier.

imported crimping force monitoring unit:100% precion and reliable detecting

two demension code gun and printer:store all the crimping data of different applicators and wires and all the data is automatically inputted.

Company and working shop

Exhibition

Certification

Contact us